Modern construction projects involve dozens of trades working simultaneously — structural steel, HVAC ductwork, plumbing, electrical, fire protection, equipment layouts, and architectural finishes all competing for the same physical space. Without a unified plan, conflicts are inevitable. That’s why coordination drawings have become a critical component of today’s construction workflow.

These drawings bring every discipline together into one coordinated model or set of documents, allowing contractors to identify clashes early, reduce rework, and keep the project moving efficiently. Below is a clear breakdown of what coordination drawings are, what services they include, why they matter, and how to choose the right provider.

What Are Coordination Drawings?

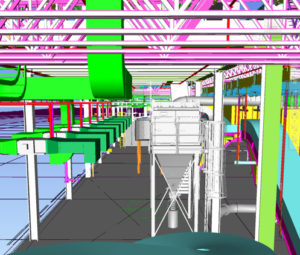

Coordination drawings are detailed, multi‑trade documents that combine architectural, structural, and MEP systems into a single, organized layout. Their purpose is simple: identify and resolve conflicts before construction begins.

Typical issues uncovered during coordination include:

- Ductwork intersecting beams

- Plumbing risers conflicting with electrical conduits

- Equipment clearances not meeting code

- Piping slopes interfering with ceilings or framing

By resolving these issues digitally, contractors avoid costly field changes and schedule delays.

What Services Are Included in Coordination Drawings?

A professional coordination package typically includes:

- Multi‑discipline integration – Combining architectural, structural, HVAC, plumbing, electrical, and fire protection drawings into one coordinated model.

- Clash detection and resolution – Identifying conflicts and proposing practical solutions.

- Shop drawing alignment – Ensuring fabrication drawings match the coordinated model.

- BIM‑based coordination – Using 3D modeling tools like Revit and Navisworks for accuracy and visualization.

- Construction‑ready documentation – Delivering drawings that field teams can install from without modification.

These services turn coordination drawings into actionable tools rather than theoretical design documents.

Why Coordination Drawings Matter

- Reduce Errors and Rework

Field conflicts lead to change orders, lost labor hours, and schedule impacts. Coordination drawings eliminate most of these issues before they reach the job site.

- Improve Project Efficiency

Clear, conflict‑free drawings allow trades to install faster and with fewer interruptions.

- Control Costs

Avoiding rework means fewer wasted materials, fewer delays, and better budget control.

- Strengthen Communication

Coordination drawings give architects, engineers, contractors, and subcontractors a shared reference point.

- Enhance Safety

Well‑planned routing reduces last‑minute field modifications that can create unsafe conditions.

Why Contractors Choose Advantage Engineering Technologies

Advantage Engineering Technologies, PLLC specializes in contractor‑focused BIM and MEP coordination. Our team integrates architectural, structural, mechanical, electrical, and plumbing systems into a single, accurate model — resolving conflicts long before they reach the field.

We prioritize:

- Precision

- Practical constructability

- Clear communication

- Fast turnaround

- Real‑world installation requirements

Contractors rely on us to reduce mistakes, save time, and keep projects on schedule.

How to Choose the Right Coordination Drawing Provider

When selecting a coordination partner, consider:

- Experience with similar project types

- Strong BIM and Revit expertise

- A defined clash detection and resolution workflow

- Clear communication with all trades

- Reliable turnaround times

The right provider ensures your coordination drawings support — not slow down — your project.

Why Hiring Professionals Makes Sense

While some teams attempt coordination in‑house, dedicated specialists deliver better results:

- Higher accuracy and detail

- Access to advanced BIM tools

- Faster turnaround

- Reduced risk of field conflicts

Professional coordination provides peace of mind and measurable project benefits. Learn more about our MEP BIM Modeling Services.

Additional Factors That Influence Coordination Success

- Project complexity – Larger projects benefit most from detailed coordination.

- Early involvement – Starting during design development yields better outcomes.

- Regular updates – Drawings must evolve as the design changes.

- Stakeholder collaboration – All trades must participate actively.

- Code compliance – Coordinated layouts must meet local building codes and standards.

Frequently Asked Questions

Q1: Are coordination drawings the same as shop drawings?

No. Shop drawings focus on fabrication details. Coordination drawings integrate all systems to eliminate conflicts.

Q2: When should coordination begin?

Ideally during design development and continuing through construction.

Q3: Do small projects need coordination?

Yes. Even small projects can experience costly clashes.

Q4: Are coordination drawings always BIM‑based?

Not always, but BIM is now the preferred method due to accuracy and visualization benefits.

Q5: Who uses coordination drawings on‑site?

Contractors, subcontractors, project managers, and field engineers.

Conclusion: Are Coordination Drawings Worth the Investment?

Absolutely. Coordination drawings are essential for modern construction. They improve accuracy, reduce risk, control costs, and streamline communication across all trades. By choosing an experienced provider and starting coordination early, you set your project up for smoother execution and fewer surprises in the field.

If you’re a mechanical, plumbing, or HVAC contractor looking for accurate, constructible, and fully coordinated drawings, Advantage Engineering Technologies is ready to help. Contact us today for a fast, detailed quote.