In today’s construction industry, accuracy, clear lines of communication, and cooperation are the cornerstones of every successful endeavor, be it a business structure, an industrial plant, or a complex infrastructure project. A frequently underestimated yet indispensable element that guarantees project effectiveness is Shop Drawing Coordination. These meticulously coordinated drawings serve as the foundation for on-site implementation, enabling architects, engineers, builders, and manufacturers to synchronize their efforts seamlessly. However, what precisely constitutes Shop Drawing Coordination, why does it hold such significance, and what advantages does it offer to a construction project? This article delves into each of these inquiries in thorough detail.

What Is Shop Drawing Coordination?

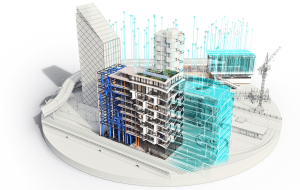

Shop Drawing Coordination involves reviewing, harmonizing, and integrating diverse shop drawings from various specialized fields—including HVAC, plumbing, fire safety, structural steel, electrical systems, and architectural specifics—to ensure seamless integration before construction begins.

Shop drawings present a heightened level of precision and granularity when contrasted with fundamental design blueprints. They delineate manufacturing specifics, dimensions, installation prerequisites, materials, interconnections, and equipment positioning. When multiple specialized teams operate concurrently, their respective drawings frequently exhibit overlapping or conflicting elements. It is within this context that Shop Drawing Coordination proactively resolves potential issues, thereby averting expensive rectification efforts.

The overarching objective is to guarantee the seamless coexistence of all systems without any interference, while adhering to design objectives, regulatory building standards, and pragmatic on-site considerations.

What Services Are Included in Shop Drawing Coordination?

Proficient Shop Drawing Coordination services encompass a comprehensive array of tasks meticulously crafted to optimize project implementation. These commonly encompass:

1. Multi-Trade Clash Detection

The coordination of shop drawings facilitates the detection of clashes involving HVAC ducts, plumbing conduits, structural support beams, and electrical raceways prior to the initiation of work.

2. Overlaying and Alignment of Drawings

Drawings originating from diverse specialized domains are superimposed onto a unified model or sheet to authenticate alignment and uphold consistent routing protocols.

3. Code Compliance Review

The meticulously coordinated drawings undergo verification to ensure adherence to prevailing building regulations, fire protection protocols, and stipulated project parameters.

4. Design Clarification with Stakeholders

Any inconsistencies or ambiguities encountered in the design are addressed through collaborative engagement with architects, engineers, and construction professionals.

5. Constructability Review

Assessment of the feasibility of constructing the design effectively on the intended site, while accounting for spatial limitations and equipment emplacement considerations.

6. Final Coordinated Shop Drawing Submission

The outcome is a comprehensive, devoid of conflicts, and practically oriented set of coordinated drawings primed for both construction and fabrication phases.

These services collectively ensure the seamless and uninterrupted progression of the construction process.

Advantage Engineering Technologies, PLLC, remains a leading example in the field, largely because of its specialized skills in the Shop Drawing Coordination. The level of detail they bring, in conjunction with their dedication to correctness and smooth cooperation between different fields, improves the efficiency and dependability of each project. They frequently provide outcomes that go above and beyond standards by finding design problems early and guaranteeing smooth integration across different specialties. Contractors, manufacturers, and engineers looking for accuracy and quality see them as reliable partners because of their professional manner, understanding of technology, and commitment to quality.

For more info, get in touch with us today!

Why Is Shop Drawing Coordination So Important?

1. It Prevents Costly Errors and Rework

Without proper Shop Drawing Coordination, conflicts across different trades can often remain undetected until the installation phase commences. Addressing these issues on-site can lead to costly delays, increased labor expenses, and material wastage. Coordinated drawings mitigate these challenges by proactively identifying and resolving conflicts before the commencement of fabrication.

2. It Improves Communication Among Teams

Construction projects necessitate collaboration among diverse stakeholders. Coordination guarantees that all parties operate from a unified plan, thus mitigating misunderstandings and misinterpretations.

3. It Enhances Project Efficiency

With clear installation paths and conflict-free layouts, each team can work faster and with greater confidence. Shop Drawing Coordination reduces downtime and improves workflow sequencing.

4. It Minimizes On-Site Delays

When all setups are prepared ahead of time, working on site becomes straightforward. Supplies show up as scheduled, directions are simple, and work teams function without any pauses.

5. It Ensures Better Quality and Accuracy

Precise and synchronized drawings ensure the final build follows the planned design and matches the technical specifications.

6. It Supports Safety Compliance

Synchronized layouts assist in keeping safe distances surrounding tools, exits, fire prevention setups, and top-level utilities.

Why Should You Hire a Professional for Shop Drawing Coordination?

Using a professional for Shop Drawing Coordination provides considerable benefits that greatly contribute to the achievement of your building project.

1. Experienced Eyes Catch Problems Early

Specialists know where disagreements often arise, such as in beam entry points, ceiling areas, equipment rooms, and shaft spaces. Their skills aid in avoiding mistakes that less experienced groups could miss.

2. Use of Advanced Software and Technology

Experts employ CAD, Revit, Navisworks, BIM systems, and disagreement-spotting tools to produce very accurate and synchronized models.

3. Clear Communication with All Trades

Specialists function as a connection involving engineers, planners, and building contractors, assuring that each person stays on the same page during the whole project.

4. Improved Fabrication and Installation Efficiency

With correctly synchronized drawings, production and setup become more rapid, decreasing project costs and timeframes.

5. Reduced Risk and Higher Reliability

Specialists ensure compliance with the design strategy, project details, and building regulations, reducing risks and fostering strong project trustworthiness.

What Vital Elements Are Required for Productive Shop Drawing Coordination?

For Shop Drawing Coordination to provide the greatest results, particular elements should be considered:

1. Early Involvement in the Project

Coordination needs to start right after the design is approved to avoid delays in production.

2. Collaboration Among All Trades

Teams working on mechanics, electrics, plumbing, structure, and planning need to team up for correct coordination.

3. Accurate Base Model and Updated Design Information

Using old or wrong design layouts causes disagreements and faults.

4. Strong Knowledge of Building Codes

Coordinators must comprehend fire regulations, electrical spacing, mechanical rules, and structural limits.

5. Space Planning and Routing Strategies

Effective routing ensures that all systems fit within ceilings, walls, and shafts without interference.

6. Continuous Review and Revision

Coordination is an iterative process requiring regular updates as the design evolves.

7. Clear Documentation and Final Approval

Well-prepared documentation helps ensure fabrication and installation follow the approved coordinated drawings.

Conclusion: Why Is Shop Drawing Coordination Critical Today?

As construction projects become more complex, the role of Shop Drawing Coordination has never been more crucial. It ensures accuracy, reduces risk, saves time, and enhances communication among all project stakeholders. With coordinated shop drawings, fabrication becomes smoother, installation becomes faster, and project delivery becomes more predictable.

Whether you are working on a commercial building, industrial facility, residential project, or infrastructure system, investing in professional Shop Drawing Coordination is one of the smartest decisions you can make. It safeguards your project from costly mistakes and ensures that every trade works together efficiently — leading to high-quality, safe, and successful construction outcomes.