Services

We provide you with a product that reflects innovation.

Our Services

Let’s Build the Future with Innovation

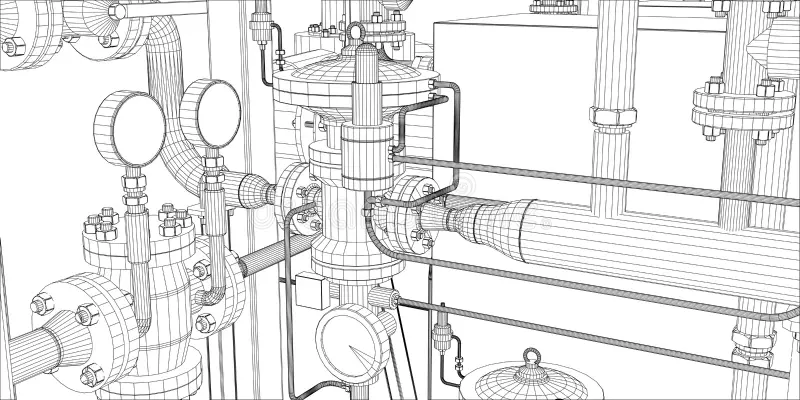

At Advantage Engineering, we are redefining the future of building design and construction through the power of Building Information Modeling (3D BIM). By representing the entire building-including all MEP (Mechanical, Electrical, and Plumbing) services-in a comprehensive 3D digital model, we identify and resolve potential conflicts before construction even begins. This advanced coordination process eliminates costly rework, reduces project timelines, and saves significant resources.

Our 3D BIM software empowers our team to think creatively and work efficiently, visualizing every aspect of a project in three dimensions-width, height, and depth-far beyond the limitations of traditional 2D drawings. We extract multiple views, sections, and isometric perspectives to provide installers with clear, precise guidance.

Beyond visualization, BIM enables automated cost estimation, material tracking, and streamlined ordering. Each component in our models is assigned detailed attributes, making it easy to select, manage, and procure routine items. For building owners, our BIM solutions support the planning and execution of preventative maintenance programs, helping to maximize the lifespan and value of your equipment investments.

Through our mastery of BIM, we are transforming how buildings, MEP systems, and utilities are planned, designed, constructed, and managed. We convert ordinary MEP objects into actionable insights, delivering value at every stage of the building lifecycle-from initial design and construction to facility management and beyond. Our BIM expertise ensures your project benefits from automatic drawing and report generation, schedule simulation, design analysis, and comprehensive facility management tools.

Choose Advantage Engineering and experience the future of building innovation-where every detail is coordinated, every process is optimized, and your investment is protected for years to come.

Shop and Coordination Drawings: Essential Tools for Modern Construction

Coordination drawings have become indispensable in today’s construction projects, regardless of size. These drawings integrate blueprints from multiple trades-such as ductwork, plumbing, mechanical piping, electrical wiring, and equipment installation-into a single, composite layout. This comprehensive approach allows for the identification and resolution of potential conflicts between systems before any work begins on site, significantly reducing the risk of costly rework and installation delays.

Key Benefits of Coordination Drawings

Clash Detection and Conflict Resolution

Coordination drawings, especially when generated from 3D BIM models, help detect and resolve spatial conflicts between MEP (Mechanical, Electrical, and Plumbing) systems and other building components, such as structural framing, ceilings, and partitions, before construction starts.

Improved Collaboration

By providing a unified reference, coordination drawings enhance collaboration among architects, engineers, contractors, and fabricators, ensuring everyone is aligned and reducing miscommunication.

Reduced Rework and Cost Savings

Early identification of clashes minimizes the need for redesigns or modifications during installation, leading to fewer RFIs (Requests for Information), reduced project costs, and shorter construction timelines.

Streamlined Installation

Installers benefit from clear, dimensioned 2D shop drawings derived from coordination models, which guide fieldwork and simplify the project engineer’s tasks, resulting in faster turnover and fewer installation errors.

Enhanced Quality and Compliance

Shop drawings provide detailed, precise instructions for fabrication and installation, ensuring adherence to project specifications and building codes, and supporting quality control throughout the project lifecycle.

How the Process Works

Integration

Blueprints from all relevant trades are compiled into a single composite drawing.

Clash Detection

Using 3D BIM, potential conflicts between systems are identified and resolved digitally.

Shop Drawing Production

Accurate 2D shop drawings are generated for use by field installers, providing clear guidance on dimensions and installation details69.

Installation

With conflicts resolved in advance, installers can work efficiently, minimizing delays and costly changes.

Conclusion

Design-Build & Design-Assist Projects

Advantage Engineering delivers value to owners by leveraging both Design-Build and Design-Assist project delivery methods, teaming up with local contractors to accelerate schedules and reduce costs.

Design-Build is a streamlined approach where a single entity is responsible for both the design and construction phases. This unified structure enhances coordination, minimizes risk, and provides the owner with a single point of contact, reducing the potential for disputes and delays. The collaborative nature of Design-Build enables early identification of fabrication and assembly opportunities, allowing for offsite coordination and improved project efficiency.

Design-Assist involves early engagement of the construction team, including key subcontractors, during the design phase. Their expertise is leveraged to improve constructability, optimize value engineering, and proactively resolve potential challenges before construction begins. This process reduces costly modifications, RFIs, and change orders, resulting in a more efficient and cost-effective project.

Our in-house HVAC shop drawing specialists, mechanical design engineers, plumbing engineers, and electrical engineering experts collaborate to create detailed MEP (Mechanical, Electrical, and Plumbing) plans and specifications. These professionals use advanced CAD systems to generate precise ductwork, piping, and coordination drawings, ensuring all building systems integrate seamlessly and efficiently.

High-quality MEP design is critical for building comfort, efficiency, and sustainability throughout the lifecycle. Since HVAC systems are significant energy consumers and play a key role in occupant satisfaction, our team prioritizes energy-efficient and adaptable solutions that meet all codes and client requirements.

By integrating Design-Build and Design-Assist approaches, Advantage Engineering delivers projects that are not only faster and more affordable but also optimized for long-term performance, operational cost savings, and occupant well-being.

Pipe Fabrication Drawings

Pipe Fabrication Drawings are essential for mechanical piping projects, enabling the pre- cutting and pre-fabrication of piping systems in a controlled workshop environment. These detailed technical drawings illustrate every aspect of the piping layout, including dimensions, materials, connections, and interactions with other systems, allowing fabricators to assemble pipe spools and components precisely before they arrive on site.

Key Benefits

- Time and Cost Savings: By preparing piping off-site, installation time is significantly reduced. Prefabricated pipes arrive ready for assembly, allowing for faster project completion and minimizing costly on-site labor and disruptions.

- Clarity and Efficiency: Each piece is clearly numbered and referenced in the drawings, simplifying the assembly process and reducing confusion for installers in the field.

- Conflict Resolution: Issues are identified and resolved during the drawing phase, which means fewer questions and change orders during installation, and less rework or material waste.

- Quality and Safety: Fabrication in a controlled environment allows for higher quality control and adherence to safety standards, improving reliability and reducing the risk of errors.

- Comprehensive Documentation: These drawings serve as a permanent record for future maintenance, repairs, or modifications, supporting the long-term management of the piping system.

Process Overview

Design and Detailing

Engineers create detailed 2D or 3D models of the piping system, specifying all components, connections, and fabrication details.

Prefabrication

Pipe spools and assemblies are fabricated in the shop according to the drawings, ensuring accuracy and consistency.

Numbering and Labeling

Each piece is labeled and referenced for easy identification and assembly on site.

On-Site Installation

Prefabricated components are delivered to the job site, where they can be quickly and efficiently installed, reducing overall project duration and minimizing fieldwork.

Product Design, Modeling and Structural Analysis (FEA)

Product design, Modeling and structural analysis (FEA).

Design automation

3D modeling and drafting

Detailed design

Engineering analysis

Tooling

Design support

CAD Customization / Automation

What We Offer

Custom CAD Solutions

We modify and extend CAD software to fit your unique workflows, integrating new tools, automating repetitive tasks, and streamlining user interfaces for greater efficiency.

Design Automation

Our automation services eliminate manual, time-consuming processes, enabling rapid drafting, automated bill of materials generation, and consistent application of design standards across projects.

Process Integration

We connect CAD systems with ERP and other business applications, ensuring seamless data exchange, improved collaboration, and accurate project tracking.

Industry-Specific Customization

From aerospace component modeling to shipbuilding layouts and oil and gas piping, we create custom libraries, templates, and automated routines that address the demands of your sector.

Error Reduction and Quality Improvement

Automated drafting and customization minimize human error, ensure compliance with industry standards, and enhance the quality and speed of deliverables.

Key Benefits

- Increased productivity and faster project turnaround through automation of routine CAD tasks.

- Enhanced accuracy and consistency in design documentation and outputs.

- Streamlined workflows and reduced project costs by integrating CAD with other enterprise systems.

- Competitive advantage through industry-specific CAD enhancements and automation.